Landian

Landian

Landian is the intelligent electric vehicle brand of Seres Group, established in March 2023, which is positioned as “the popularizer of intelligent electric vehicles” and is committed to providing cost-effective new energy models for home users. Relying on the technical accumulation of Seres Group in the field of electrification, the brand shares its core technologies (such as DE-i super electric drive intelligent platform and high safety battery system) and intelligent manufacturing system, and focuses on practicality and intelligence with the core values of “real, stylish, new, and rising”. Landian adopts an autonomous operation model, with R&D, production and sales all led by Seres, while cooperating with BYD FDD and Huawei to strengthen product competitiveness in the fields of hybrid system and intelligent ecology.

Currently, the mainstream products under the Landian brand include Landian E3, Landian E5 and Landian E5 Plus.

Aicar sell cars to dozens of countries and regions around the world. We welcome interested customers to visit our company, tour the factory, and find the right brand for cooperation. The following is the Landian vehicle models that we are selling.

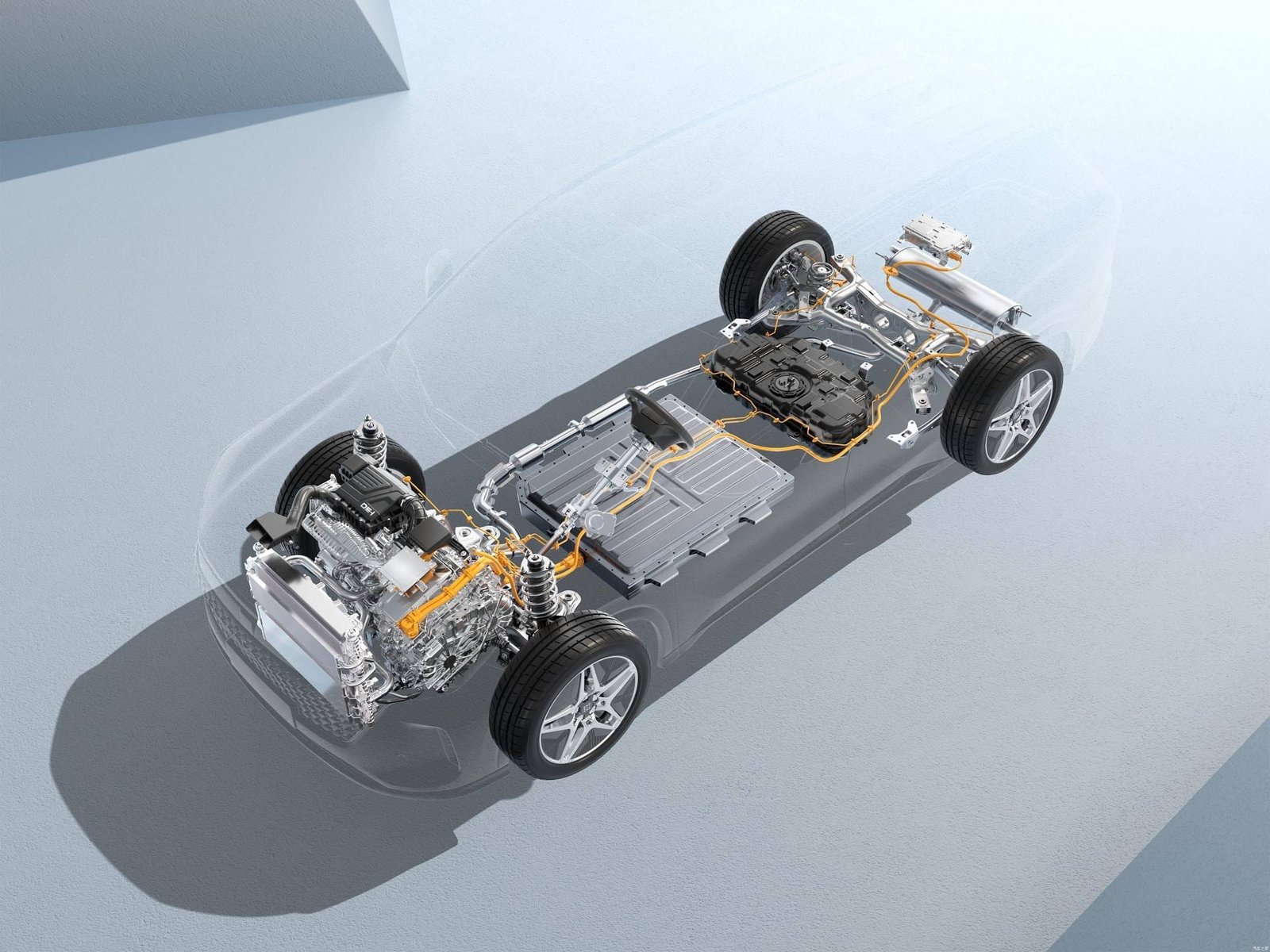

Seres Super Electric Hybrid System (DE-i Platform)

This platform is one of Landian’s core technologies, integrating a high-efficiency plug-in hybrid special engine with the DHT300 electric hybrid system, supporting pure electric, range extender and hybrid multi-mode drives. Its 1.5L engine adopts Miller cycle and low-pressure EGR technology, with a thermal efficiency of 42.53%, paired with E-CVT continuously variable transmission, WLTC feed-in fuel consumption of only 5.5L/100km, and a comprehensive range of up to 1,300km. the platform pioneered the multi-motor drive architecture, which realizes sensorless shifting through the 2DHT electro-mechanical coupling, with a zero hundred acceleration of 7.8 seconds, and a deep-sea-level NVH quietness standard, and is compatible with lithium-phosphate (Li-phosphate) and three-cylinder electric hybrid systems. It is also compatible with lithium iron phosphate, lithium ternary and sodium ion batteries. the DE-i platform has been granted more than 3,500 patents, of which nearly 300 are invention patents, and its technical indexes are in the first echelon of the industry.

Ferdi Electric Hybrid System (Jointly developed by BYD)

Landian E5 series is equipped with BYD FDD power hybrid system, including 1.5L high-efficiency plug-in hybrid special engine and DHT300 electric hybrid system, which is mainly electric drive, and the proportion of electric drive in full working conditions is over 80% (99% in urban conditions). The maximum power of the engine is 81kW, the power of the motor is 130kW, the peak torque is 300N-m, and the acceleration from 0-50km/h is only 2.9 seconds, which combines strong power with low energy consumption. The system balances energy consumption, battery life and NVH performance through intelligent algorithms, supporting a pure electric range of 165km (CLTC) and a combined range of 1,300km, realizing a flexible energy strategy that uses electricity for short distances and complements oil and electricity for long distances.

HUAWEI HiCar 4.0 Intelligent Cockpit

Developed in deep cooperation with Huawei, it is equipped with a Qualcomm chip and a 15.6-inch full HD floating large screen, supporting voice partition control, continuous command recognition and customized function settings. The system integrates Huawei’s ecology, with a response speed of 500ms level, and the first lip movement recognition technology, with a command recognition accuracy rate of over 90% in noisy environments. For example, users can directly adjust air conditioning, switch driving modes, and seamlessly interconnect with their smart homes through voice or lips to create an immersive interactive experience.

Industry 4.0 Intelligent Manufacturing System

Landian relies on Seres intelligent factory to realize 100% automation of key processes with 1000+ intelligent robots. 240 robots are used in the welding workshop to complete fully automated welding, and 37 ABB robots execute spraying in the painting process. By connecting the MES system through 5G private network, it realizes the transparent monitoring of the whole production process, and the defective rate tends to be close to zero. The factory has been awarded the title of “Lighthouse Factory”, the R&D cycle of a single model has been shortened to 18 months, and the quality control system covers the inspection of parts and components at the factory to the 50km high-speed road test, ensuring that the vehicles leave the factory with “0 faults”.

Brands

Auto Models

Countries

Customers

You can find us at

john@aicarglobal.com

+86 15161169607

LOCATION

Nanjing International Cyberport, Xuanwu District, Nanjing, Jiangsu Province