Neta Battery Management System (BMS): the core guardian of the smart energy era

In the global trend towards carbon neutrality and the energy transition, batteries have become the key to the development of electric vehicles, smart grids and renewable energy sources as a carrier for storing and releasing green energy. As the “smart butler” of the battery, the battery management system (BMS) has become the underlying technical support for unlocking the performance potential of the battery and ensuring the stable operation of the system through real-time monitoring, precise regulation and safety protection.

Core function: closed-loop management from data to decision-making

The core mission of the BMS is to achieve intelligent management of the entire battery life cycle. Its functions include

multi-dimensional data collection: real-time acquisition of battery status through voltage, current, and temperature sensors to establish a dynamic database. For example, the BMS can accurately detect the risk of overcharging or over discharging of individual cells and promptly cut off the circuit to prevent thermal runaway.

Equalization management: To address the differences between individual cells in a battery pack, BMS uses passive discharging or active energy transfer technology to solve the “cask effect” and improve overall efficiency. For example, in electric vehicles, equalization technology can extend the life of the battery pack by more than 20%.

Thermal management: The temperature of the battery is regulated by a fan, liquid cooling system or heating film to ensure that it is in the optimal operating range of 25-40°C. In extreme environments, BMS can even predict temperature trends and activate protection mechanisms in advance.

Communication and collaboration: Based on protocols such as CAN bus and Ethernet, the BMS seamlessly interfaces with the vehicle control system or the grid dispatching platform to dynamically optimize charging and discharging strategies. For example, in a fast charging scenario, the BMS adjusts the current through real-time communication to balance efficiency and safety.

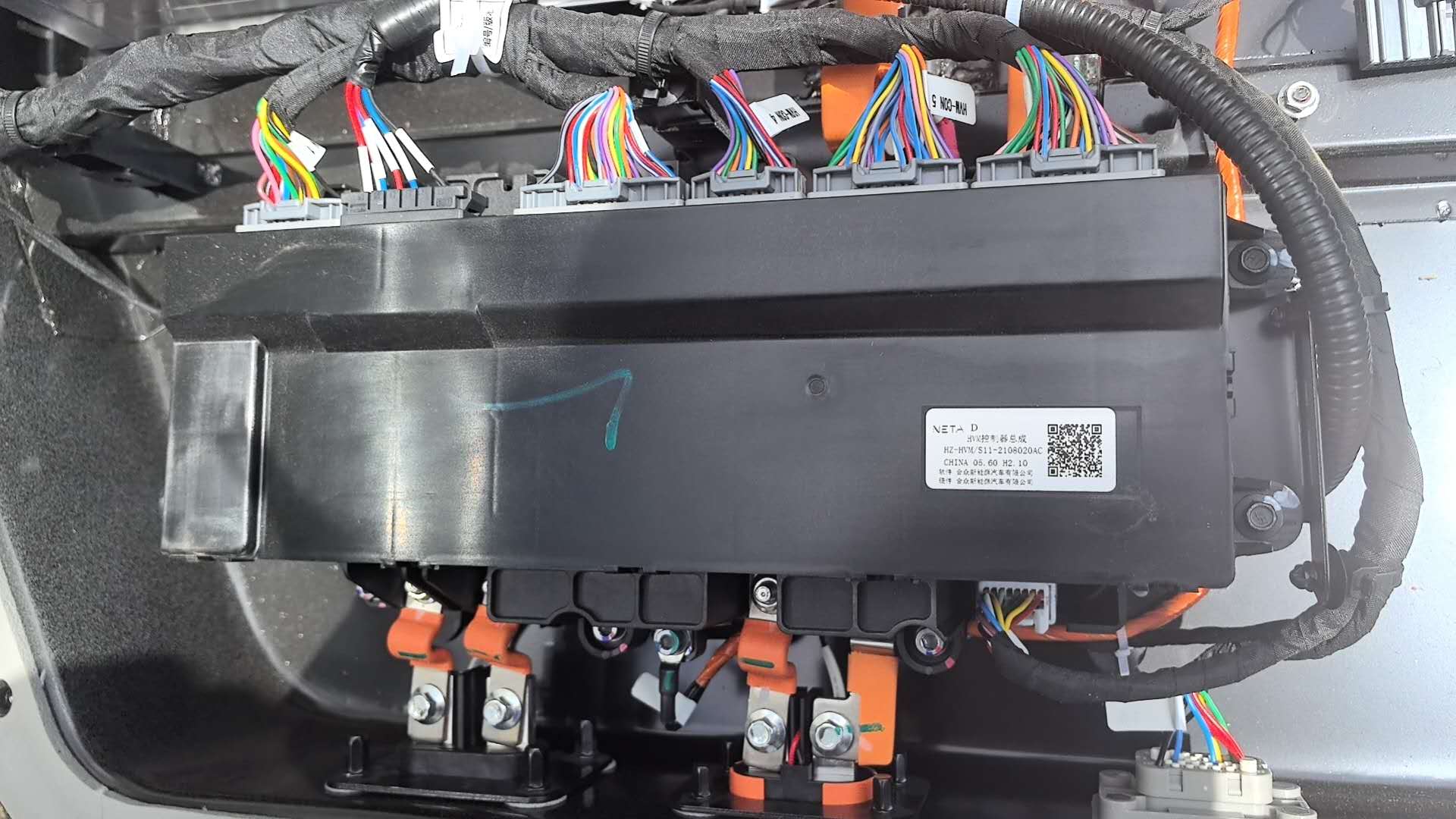

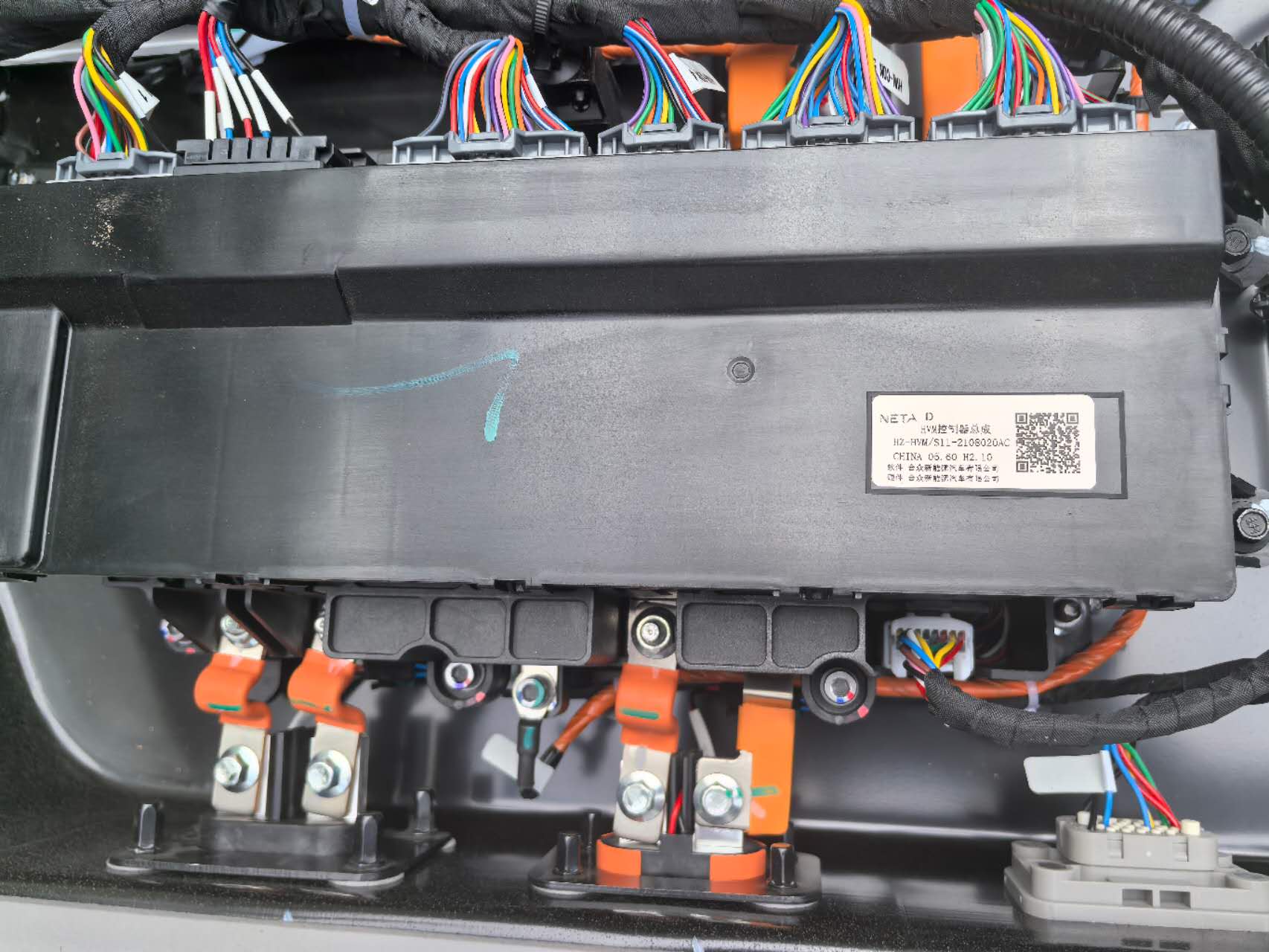

System architecture: distributed and modular technological evolution

Modern BMSs mostly use a “master-slave” architecture, with a layered design to improve scalability:

Main board (BMU): integrates data processing and communication modules, is responsible for SOC (state of charge) and SOH (state of health) estimation, and interacts with external systems.

Slave board (BCU): directly connected to individual battery cells, performs voltage/temperature acquisition and equalization control, and uses daisy chain or CAN bus communication to reduce wiring complexity.

High-voltage control unit: manages relays, pre-charge circuits, and insulation detection to ensure the safety of high-voltage systems.

Application scenarios: from consumer electronics to smart grid

BMS applications have penetrated many fields:

Electric vehicles: Optimize range and prevent capacity loss due to battery aging. For example, Tesla’s BMS predicts battery life through AI algorithms to precisely plan charging and discharging strategies.

Energy storage systems: In grid-level energy storage, the BMS coordinates the charging and discharging of the battery pack to improve energy utilization efficiency and support peak shifting.

Industry and robotics: In automated equipment, BMS ensures a stable power supply under high load conditions and reduces the risk of downtime through fault warnings.

Future trends: AI-driven and architectural innovation

BMS technology is evolving towards being smarter and more integrated:

AI and big data integration: Machine learning is used to analyze historical data, achieving a SOH prediction error of less than 3% and optimizing charging and discharging strategies.

Wireless BMS: Bluetooth or Wi-Fi technology is used instead of traditional wiring harnesses to reduce system complexity and cost. For example, BMW and GM have already deployed related technologies.

Electrochemical impedance spectroscopy (EIS): Companies such as Marelli have integrated EIS into the BMS to accurately diagnose the degree of battery aging through impedance changes and provide early warnings of failure risks.

Domain control integration: BMS, motor control, and on-board chargers are integrated into a single domain controller to improve system response speed and energy efficiency.

Reviews

There are no reviews yet.